News

VanJee released hybrid solid-state 128-wire automotive-grade LiDAR

Dec 16,2021

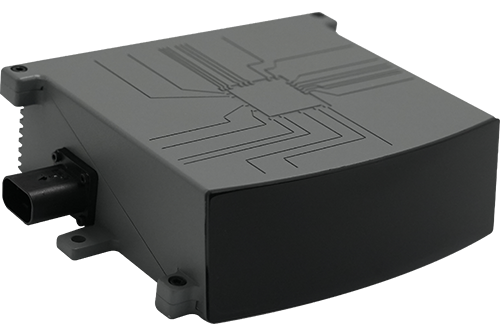

On December 16, VanJee released a hybrid solid-state 128-wire automotive-grade LiDAR at the World Smart Car Conference in Guangzhou.

The launch of a high-beam LiDAR was an important practical and technical accumulation of the VanJee's adherence to the parallel development of multiple technical forms in this field.

This LiDAR would further improve VanJee's front-loaded vehicle-level LiDAR product layout and meet the technical research and development needs of mass-produced autonomous vehicles.

As the eyes of self-driving cars, LiDAR became the core sensor for cars to develop high-level autonomous driving.

Compared with traditional millimeter wave, visual recognition and other sensors, LiDAR had significant advantages in strong light, night, and high-speed driving environments. The ability to obtain environmental depth information enabled LiDAR to achieve more accurate perception of targets and had strong complementarity with other sensors.

And LiDAR was also important sensing units for the development of multi-sensor fusion.

LiDAR is developing towards high-strength, solid-state, integrated and chip.

Before a new generation of technology is immature, mirror-turning LiDAR is still one of the products that can achieve vehicle-level mass production in the field of high-level autonomous driving.

Wang Xuesi said at the meeting that the core elements of LiDAR's front-loading mass production lied in four aspects: intelligence, high reliability, high performance and low cost.

■ Maximum range of 200 meters, pixel-level resolution, excellent overall performance

VanJee released a mid-to-long-range LiDAR this time. This mid-to-long-range LiDAR applied to the application scenario of automotive-grade autonomous driving with up to 200m measuring range, 0.2° angular resolution, 20Hz scanning frequency.

In high-speed scenarios, this LiDAR could ensure that the vehicle at 100km/h had sufficient reaction time and braking distance.

In urban low-speed and complex traffic scenarios, this LiDAR could output more than 1.43 million point cloud data per second. And this LiDAR also could accurately detect traffic participants and obstacles with the 120°×25.4° field of view angle such as vehicles, pedestrians, railings, road shoulders, etc.

■ Vehicle-grade development with high stability

■ Vehicle-grade development with high stability

In order to further control the cost and improve the stability of LiDAR operation, VanJee adopted vehicle-grade components and integrated design at the beginning of the design. Then VanJee also iterated self-developed SOC chip solution in subsequent versions.

In terms of mechanical, functional and electrical safety, VanJee added redundant design.

And VanJee ensured that the equipment could still operate with high reliability under extreme conditions through double backup of Product Mission Critical Model.

According to the deep understanding of quality requirements for auto parts, VanJee established a complete vehicle-level testing process and specifications through cooperation with many OEMs.

The 128-line LiDAR products undergone more than 60 professional tests in 7 categories, including high and low temperature, thermal shock, vibration, salt spray, and EMC. These tests ensured the 128-line LiDAR’s stability in harsh vehicle environments.

■ Completed an industry-leading manufacturing center with an annual production capacity of 300,000 units

VanJee had ten years of R&D and production experience in the field of LiDAR,

VanJee always regarded LiDAR industrialization and large-scale application on vehicles as the goal of product development.

Based on the judgment of market trend, VanJee began to establish an international leading manufacturing center in 2018 and

VanJee also built a production capacity matching the corporate strategies to meet the stringent requirements of LiDAR in terms of R&D testing, quality technology and market supply.

VanJee completed the construction of second phase of 27,500-square-meter Shunyi production and scientific research base.

This base had a CNAS-certified vehicle-level laboratory, a 10,000-level dust-free workshop and an advanced automated production line. The planned annual production capacity reached 300,000 units.

And this base also was capable of providing professional services for global auto brands support and bulk supply to accelerate the development of LiDAR’s industrialization.